Provide you with the latest company and industry news.

Conveyor chain sprockets are an essential component of industrial conveyor systems, responsible for transferring power and motion from one part of the system to another. These sprockets are specifically designed to engage with the links of the conveyor chain, allowing for smooth and efficient movement of materials and products along the conveyor line.

The primary function of conveyor chain sprockets is to transmit torque from the motor to the conveyor chain, which is responsible for moving the materials along the conveyor line. Without sprockets, the conveyor system would not be able to operate as intended, resulting in downtime and reduced productivity.

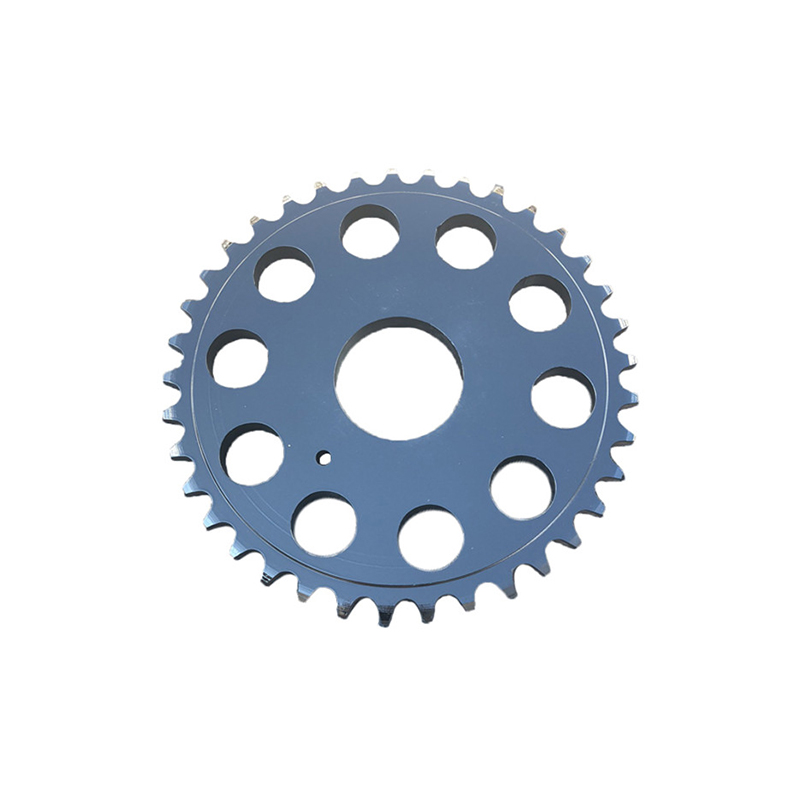

The design and selection of conveyor chain sprockets can have a significant impact on the performance and efficiency of the conveyor system. The size, shape, and number of teeth on the sprocket must be carefully chosen to match the specifications of the conveyor chain, ensuring optimal engagement and transfer of power.

Additionally, the material composition of the sprocket is crucial, as it must be able to withstand the rigors of continuous use in industrial settings. Sprockets made from durable materials such as hardened steel or cast iron are commonly used for this purpose, as they are able to withstand high loads and resist wear and tear.

Regular maintenance and inspection of conveyor chain sprockets is also essential for ensuring the longevity and performance of the conveyor system. Proper lubrication and periodic replacement of worn or damaged sprockets can prevent costly downtime and reduce maintenance costs over time.

In conclusion, conveyor chain sprockets are critical components of industrial conveyor systems, responsible for transmitting power and motion from the motor to the conveyor chain. Proper design, selection, and maintenance of these sprockets are essential for ensuring optimal performance and efficiency of the conveyor system, ultimately contributing to increased productivity and profitability for industrial operations.

Casting steel sprocket type A 2 inch big chain sprocket for winch is suitable for die forging scraper chain. The sprocket is double, with a hub in the middle. The wheel piece is assembled on the hub, which is easy to assemble. The wheel piece is quenched and tempered as a whole, and the teeth are hardened at high frequency, making the teeth harder and more wear-resistant.

韩语

韩语 阿拉伯语

阿拉伯语 西班牙语

西班牙语