Provide you with the latest company and industry news.

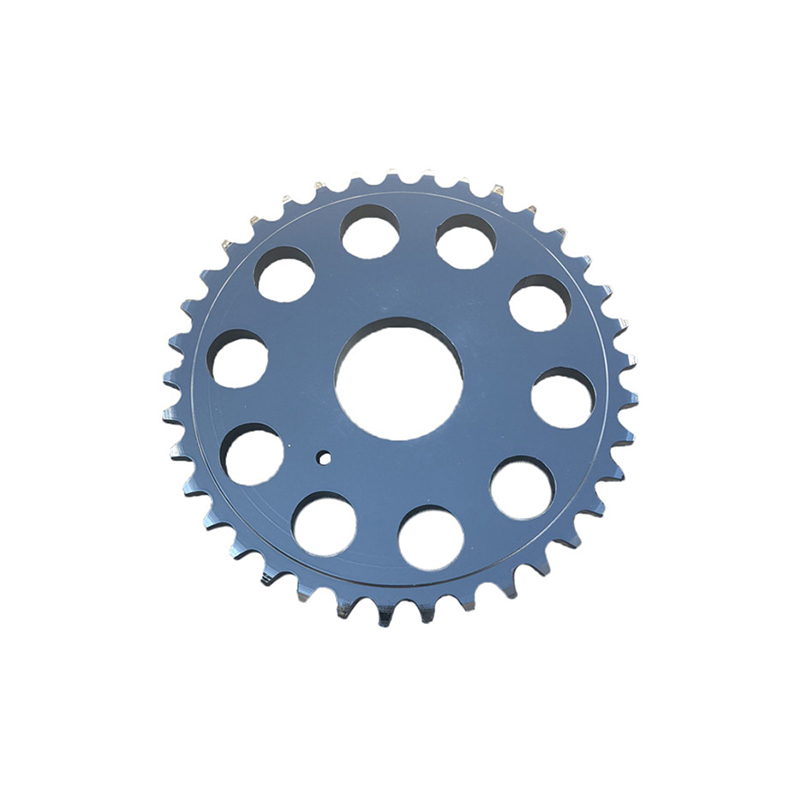

Mini chain drive sprockets, like standard sprockets, are produced using various manufacturing methods, depending on factors such as the required precision, material, and production volume. Here are common production methods for mini chain drive sprockets:

Machining:

Machining is a versatile method used to produce mini chain drive sprockets. Computer Numerical Control (CNC) machining centers can precisely cut and shape sprockets from a solid piece of metal (e.g., steel or aluminum). This method is suitable for small to medium production runs and allows for tight tolerances and customization of sprocket specifications.

Stamping:

Stamping is a cost-effective method for producing large quantities of simple, low-profile mini sprockets. A sheet metal material is stamped into the desired sprocket shape, and teeth are formed using punches and dies. Stamped sprockets are often used in lightweight and low-torque applications.

Injection Molding (Plastic Sprockets):

Mini chain drive sprockets made of plastic, such as nylon or polyethylene, are commonly produced through injection molding. In this process, molten plastic is injected into a mold cavity, where it solidifies to form the sprocket shape. Injection molding is suitable for high-volume production of lightweight sprockets.

Sintering (Powder Metallurgy):

Sintering is used to produce mini sprockets from powdered metal materials. The metal powder is compacted into the desired shape and then subjected to high-temperature sintering. This process fuses the metal particles together, creating a solid sprocket. Sintering is ideal for sprockets with complex shapes and is often used in applications requiring self-lubricating sprockets.

Hobbing:

Hobbing is a precision machining process used to create teeth on mini chain drive sprockets. A hobbing machine with a specialized cutting tool (hob) is used to cut teeth into a blank sprocket. This method is suitable for producing sprockets with accurate tooth profiles and is commonly used for high-precision applications.

Wire EDM (Electrical Discharge Machining):

Wire EDM is a precise machining method used for producing intricate mini sprockets. It involves using an electrically charged wire to precisely remove material and create the sprocket's tooth profile. Wire EDM is ideal for sprockets with complex shapes and tight tolerances.

Additive Manufacturing (3D Printing):

Additive manufacturing, often referred to as 3D printing, is a relatively new method for producing mini sprockets. It involves building up material layer by layer to create the sprocket's shape. 3D printing allows for design flexibility and can be suitable for rapid prototyping and low-volume production.

The choice of production method depends on factors such as material selection, production volume, cost considerations, and the required level of precision. Mini chain drive sprockets are used in a wide range of applications, including robotics, small machinery, and precision equipment, where their quality and reliability are critical. Manufacturers select the most suitable production method based on the specific requirements of the sprocket and the intended application.

한국어

한국어 عربى

عربى Español

Español